OFFSHORE CARGO SOLUTIONS

DESIGN & ENGINEERING SERVICES

Our customers require to ship valuable and sensitive tools and equipment for installation or use offshore. Handling and shipping, especially in what can be an extremely hostile offshore environment, can place onerous and unpredictable loads on equipment which they may not have been designed to withstand. In some cases traditional offshore containers will not offer sufficient capacity or adequate protection, stability or restraint to ensure safe and undamaged arrival at their destination.

Nodal designed offshore freight containers and cargo baskets are bespoke engineered to suit specific cargo requirements and certified in accordance with DNV 2.7-1 (for gross weights up to 25,000 kg) or 2.7-3 (for portable offshore units).

These containers do not require spreaders, and can be lifted anywhere worldwide by any crane with sufficient capacity and are suitable for repeated use.

Liaising directly with DNV or Lloyd's and the client or end user, we guarantee we will achieve the appropriate certification and a finished design which meets client requirements for safety, functionality and ease of use.

Our tailored equipment shipping baskets provide the necessary protection during transit to extremely valuable and sensitive components ensuring they will be delivered to their destination ready for use.

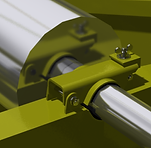

All baskets are designed with safety, useability and functionality as a priority. All necessary clamps, rollers, tugging points and supports necessary to provide ease of use, sound support and restraint for the most onerous transit and operational conditions shall be provided for, whether off-the-shelf items or specially designed bespoke components.

WHAT IS A DNV 2.7-1 CONTAINER?

DNV 2.7-1 certified offshore containers and cargo baskets are specifically designed for dynamic lifting via padeyes and a DNV certified lifting sling set equipped with shackles. They are inspected at the design stage, material procurement, production and final load & NDE tested. Not only is a prototype tested, but a specified number of randomly selected units from each batch are tested. These containers have solid steel construction, including the flooring.

They are required to have a uniquely identified DNV certified lifting set, significantly stronger steel, more stringent production compliance and to have all the testing documentation to prove their worthiness for the rigors of offshore conditions.

DNV review their standards every few years to ensure newly certified equipment meets and exceeds current safety and engineering requirements.