LIFTING APPLIANCES

LIFTING EQUIPMENT SERVICES

Where specialist, non-standard lifting equipment is necessary to conduct a lifting operation in a controlled, safe and efficient manner, Nodal have the engineering experience, technical know-how and proven track record to provide the right solution. We work closely with our customers to discuss requirements, offer our own input, and establish design criteria before moving on to the design, verification, third party approval and supply the following types of equipment:

-

Runway Beams

-

Bespoke Lifting Equipment

-

BOP Handling Equipment

-

Loose Gear (Link Plates, Spreaders, Clamps etc)

We work with DNV , Lloyd's and other industry recognised codes and standards to ensure the final product is fully compliant with current regulations and safe for use.

Nodal lifting equipment can offer the following benefits:

-

Safer lifting operations

-

More efficient lifting operations

-

Reduced labour costs due to simpler lifting operations

-

Save time offshore

-

Bespoke designs to suit unique requirements

The investment in Nodal bespoke lifting equipment upfront can pay dividends offshore in terms of time and labour costs saved, not to forget the benefits of increased safety to personnel involved in lifting operations.

CRANE SUPPORT SERVICES

Cranes are an essential component in the day to day safe handling of heavy equipment aboard offshore installations and vessels. Crane operational capabilities can be limited by various factors including ageing, original design specification, and mounting location.

Nodal provide detailed engineering reviews including abnormal weight crane analyses for one-off lifts, damaged crane boom capacity assessment and fatigue life assessment of crane structures.

CRANE AUXILIARY EQUIPMENT DESIGN

AUXILIARY EQUIPMENT

Nodal specialise in the design of auxiliary equipment to support, enhance or facilitate unusual and unique crane lifting operations, where an existing crane would otherwise not be suitable for the task in hand.

Our services in this area include:

-

Front End Concept Development

-

Design & Engineering

-

Verification

-

Crane Structure Analysis and Capacity Review

-

Liaising with Verification Bodies

We have a proven track record in delivering successful crane modification projects.

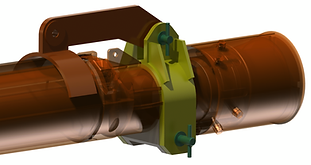

ANTI-CABLING SYSTEMS

Subsea installations are being performed in deeper water then ever. Instances of “cabling” where torsional instability in a multi-fall hoist leads to spinning of the block and the rope intertwining on itself become more likely as fall length increases and the risk of this must be mitigated against.

One solution is to replace the wire rope with another providing increased rotation resistance. This may not always be practical due to cost or time restrictions.

Another solution to reduce the risk of cabling and add a sufficient margin of safety is to increase the topside spacing between rope falls in proportion to the height of lift.

Nodal have successfully design engineered anti-cabling topside separation systems in partnership with our customers to allow subsea installations on 2-falls to a block depth of 850 metres.

This type of anti-cabling system can be retro-fitted to an existing vessel or installation and simply removed when not required.